先进润滑与表界面技术研究所

基本情况

|

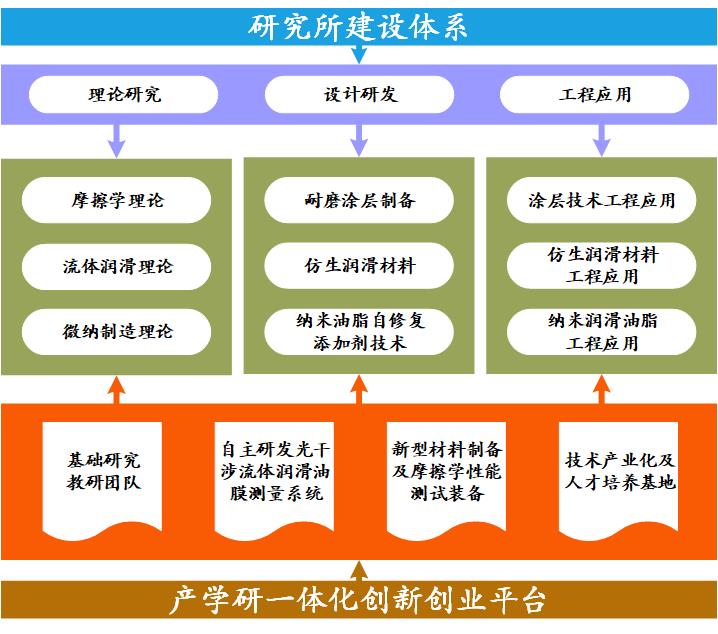

先进润滑与表界面技术研究所,依托北京交通大学“载运工具先进制造与测控技术教育部重点实验室”,以发展学科基础理论、解决重大工程问题为使命,定位于应用基础和高新技术研究。围绕摩擦学理论与技术、机械表面/界面科学与性能控制、生物摩擦学与生物机械、微纳制造理论与技术等方面的基础研究和应用基础研究,注重机械、材料、物理、化学与生物等多学科交叉与深度融合,同时,开展关键零部件摩擦学基础理论、表界面摩擦效应、先进功能涂层材料设计、服役寿命精准预测理论等相关的应用技术研究并提供技术咨询服务,探究典型服役环境润滑油/润滑脂的摩擦化学机理和材料减摩与抗磨技术的原理与方法,发展/完善高性能耐磨涂层材料设计、制备与表界面性能调控理论,并助推新型耐磨涂层材料与技术的产业示范推广与应用,为高新技术机械装备发展和安全服役提供理论和技术保障,先进润滑与表界面技术研究所建设体系如图1所示。 图1 研究所建设体系 |

研究方向

|

研究所主要从事先进润滑与表界面技术、以及生物润滑技术的相关研究,具体包括:纳米润滑油脂研发和工程应用研究、耐磨防腐多功能涂层的制备和工程应用技术研究、装备润滑仿真分析,仿生润滑材料设计及摩擦机理研究。面向国家战略,紧密结合我国航空航天、国防工业及军事装备建设需要,采用产学研用模式、高科技创新研发机制,取得了一批国际先进、国内领先水平的科研成果,部分成果达到国际领先水平。主要研究方向如图2所示。

图2 团队主要研究方向 (1)纳米润滑油脂研发和工程应用研究 磨损表面原位自修复是在机器运行过程中自动进行的,是表面工程领域的一项新技术,也是一种主动维修技术,能够节省大量人力物力,因而日益受到重视。 针对高端装备机械零部件在高/低温、真空/大气、辐射等严苛环境下低磨损甚至零磨损的需求,发展高端磨损修复技术和产品。 (2)耐磨防腐多功能涂层的制备和工程应用技术研究 探索和开发含硅酸盐类润滑相的高温低摩擦磨损防腐涂层技术,发展能够在多种介质环境下长期服役的高/低温自适应固体润滑涂层体系,并建立其摩擦学理论和损伤机制,保障高端装备关键零部件的服役要求,促进苛刻工况下低摩擦自适应耐腐蚀涂层相关理论的发展。 (3)装备润滑机制研究 针对轴承齿轮等基础零部件的设计和应用需求,建立润滑和磨损统一的理论模型,研究润滑和磨损互相影响的演化规律,探索不同工况参数和材料参数等对于润滑和磨损状态的影响,针对典型接触副的磨损形式提出若干抗磨方法,为摩擦副润滑抗磨技术研发提供理论支撑。 (4)仿生润滑材料设计及超滑机理研究 以仿生滑液和仿生润滑材料作为研究对象,分别对磷脂和磷脂复合物的摩擦行为和吸附结构进行探索,揭示在仿生承载表面聚醚醚酮(PEEK)与氮化硅(Si3N4)之间的潜在润滑机制。其次,通过化学和物理交联作用,在水中合成了氧化石墨烯(GO)纳米片与两性离子聚甲基丙烯酸磺甜菜碱(PSBMA)组成的纳米复合水凝胶。GO纳米片在水凝胶中分散良好,并通过静电相互作用有效地交联到甲基丙烯酸磺甜菜碱(SBMA)聚合物链中。在引入GO纳米片后,PSBMA水凝胶的抗压应力显著增强(提高了近5倍),摩擦系数(COF)显著降低(下降了大约52-76%)。

|

科研成果与荣誉

1.研究成果(1)发展了硅酸盐类纳米自修复材料的合成和制备技术,开发了一系列性能优异的磨损自修复润滑油脂添加剂产品。 (2)以本所自行合成的纳米羟基硅酸盐材料作为固体涂层的关键填料,开发了一系列性能优异的润滑耐磨抗腐蚀涂层,其在高温环境下可以实现超低摩擦(摩擦系数<0.01),耐磨寿命大幅度延长。 (3)针对不同零部件的设计开发了不同的润滑仿真程序。 (4)开发了磨损自修复性能评价方法和设备。 2.知识产权 研究所知识产权统计参见表1。 表1 成果涉及的知识产权清单

|

代表性科研项目

|

近5年主要科研项目:

|

代表性论著

|

近5年发表的主要论文: [1] Chang Qiuying*, Rudenko P, Miller DJ, Wen J, Berman D, Zhang Y, Erdemir A. Operando formation of an ultra-low friction boundary film from synthetic magnesium silicon hydroxide additive. Tribol Int 2017;110:35–40. (WOS:000398871700004) [2] Wang B, Chang Qiuying*, Gao K, Fang HR, Qing T, Zhou NN. The synthesis of magnesium silicate hydroxide with different morphologies and the comparison of their tribological properties. Tribol Int 2018;119:672–679. (WOS:000424960500065) [3] Gao K, Chang Qiuying*, Wang B, Zhou N, Qing T. Synthetic magnesium silicate hydroxide nanoparticles coated with carbonaceous shell in subcritical water condition. Appl Surf Sci 2018;450:312–317. (WOS:000433199000036) [4] Gao K, Chang Qiuying*, Wang B, Zhou N, Qing T. The tribological performances of modified magnesium silicate hydroxide as lubricant additive. Tribol Int 2018;121:64–70. (WOS:000428605700007) [5] Gao Kai, Chang Qiuying*, Wang B, Zhou N, Qing T. The purification and tribological property of the synthetic magnesium silicate hydroxide modified by oleic acid. Lubrication Science 2018;30(7):377–385. (WOS:000446306000004) [6] Wang Bin,Chang Qiuying*,Gao Kai. A hydrothermal reacting approach to prepare few-layer graphene from bulk graphite, Appl Surf Sci 2019;479:20–24. (WOS:000464931800003) [7] Chang Qiuying*, Wang Bin, Gao kai. Pressure-dependent anti-wear mechanisms of synthetic magnesium silicate hydroxide nanoparticles. Tribol Int 2019;135:230–236. (WOS:000469157500024) [8] Chang Qiuying*, zhang Hao, Gao Rongqin. Magnesium silicate hydroxide modified by carbon from hydrothermal carbonization of gelatin for tribological application. Diamond & Related Materials 2019;95:36–43. (WOS:000470338300006) [9] Chang Qiuying*, Zhang Hao, Gao Rongqin. Amorphous Carbon Doping Nano‑Magnesium Silicate Hydroxide with Significant Tribological Property. Tribology Letters 2019;67:76. (WOS:000472523700001) [10] Zhang Hao,Chang Qiuying*. Friction-induced rehybridization of hydrothermal amorphous carbon in magnesium silicate hydroxide-based nanocomposite. Carbon 2019; 155:650-659. (WOS:000491864400075) [11] Gao Kai, Chang Qiuying, Wang B. The dispersion and tribological performances of magnesium silicatehydroxide nanoparticles enhanced by Span60 oleogel. Journal of Sol-Gel Science and Technology 2020,94(1):165-173;(WOS:000492658400002) [12] Gao Kai, Chang Qiuying*, Wang B, Gao Rongqin, He Jing. Preparation of Fe3O4@C composite nanoparticles with core-shell structure in subcritical water condition. Diamond & Related Materials 2020;101,107627:1-6. (WOS: 000510954000025) [13] Wang B, Chang Qiuying*, Gao Kai. Hydrothermal synthesized magnesium silicate hydroxide/graphene nanocomposites in a MgO-SiO2-graphite-H2O alkaline system and its application in anti-wear additive toward infinitesimal wear. Tribology International 2020;148,106313:1-8. (WOS: 000530851300018) [14] Wangbin, Chang Qiuying*, Gao Kai, Tian Yu. Super low Wear Realizable Tribofilms from Lubricant Oi lContaining Hydrothermally Synthesized Magnesium Silicate Hydroxide/Carbon Core−Shell Nanoplates. Langumir 2020; [15] Gao Rongqin, Liu wenbo,Chang Qiuying*,et.al. Tribological Property of Biocarbon-Based Magnesium Silicate Hydroxide Nanocomposite as Lubricant Additive at Different Concentrations of Additive and Dispersant. Journal of Tribology 2021;143: 071901(WOS:000656438600004) [16] Zhanghao, Chang Qiuying*, Fluorine‑Doped Amorphous Carbon‑Coated Magnesium Silicate Hydroxide as Lubricant Additive and Atomic Simulation. Tribology Letters 2021: 69:11 (WOS:000610571600002) [17] Zhanghao, Chang Qiuying*, Enhanced ability of magnesium silicate hydroxide in transforming base oil into amorphous carbon by annealing heat treatment. Diamond & related Materials 2021;117:108476,(WOS:000684377500002) [18] Wangkai, Chang Qiuying*, Ultra-Low Wear and Anti-Oxidation Properties of Microcrystalline Graphite Oxide-Magnesium Silicate Hydroxide Composite Nanoadditives in the Poly-Alpha-Olefin Base Oil, Journal of Tribology 2021; 144(3):1-23 [19] Gao Kai, Chang Qiuying*, Wang Bin, Gao Rongqin. The tribological response of nanoparticles' equivalent diameter to the oil film thickness, Lubrication Science 2021; 33:450-459.( WOS:000692920500001) [20] Wang Bin, Gao Kai, Chang Qiuying, et.al. Magnesium Silicate Hydroxide-MoS2-Sb2O3 Coating Nanomaterials for High-Temperature Superlubricity, Applied Nano Materials 2021, 4:7097-7106. |

联系方式

|